Sapphire

Impex HighTech GmbH offers a wide range of products made of synthetic sapphire. This material is used for the manufacture of precision optics, domes, high-pressure components and other optics.

Some of our main products

- Sapphire substrates

- Sapphire domes (ground and polished)

- Sapphire windows for standard optical applications

- Precision windows (laser, analytics, measurement technology)

- Sapphire window with very large aperture

- High temperature window

- High pressure window

- Scanner window

- High pressure pipes

- Sapphire tubes and sapphire crucibles (chemical industry)

- Sapphire light guide (Beauty Care/Dermatology )

- Sapphire tips/sapphire scalpels (laser surgery)

- Bearing jewels

- Sapphire components on specific request

- Sapphire optics from stock

Synthetic monocrystalline sapphire (Al2O3)

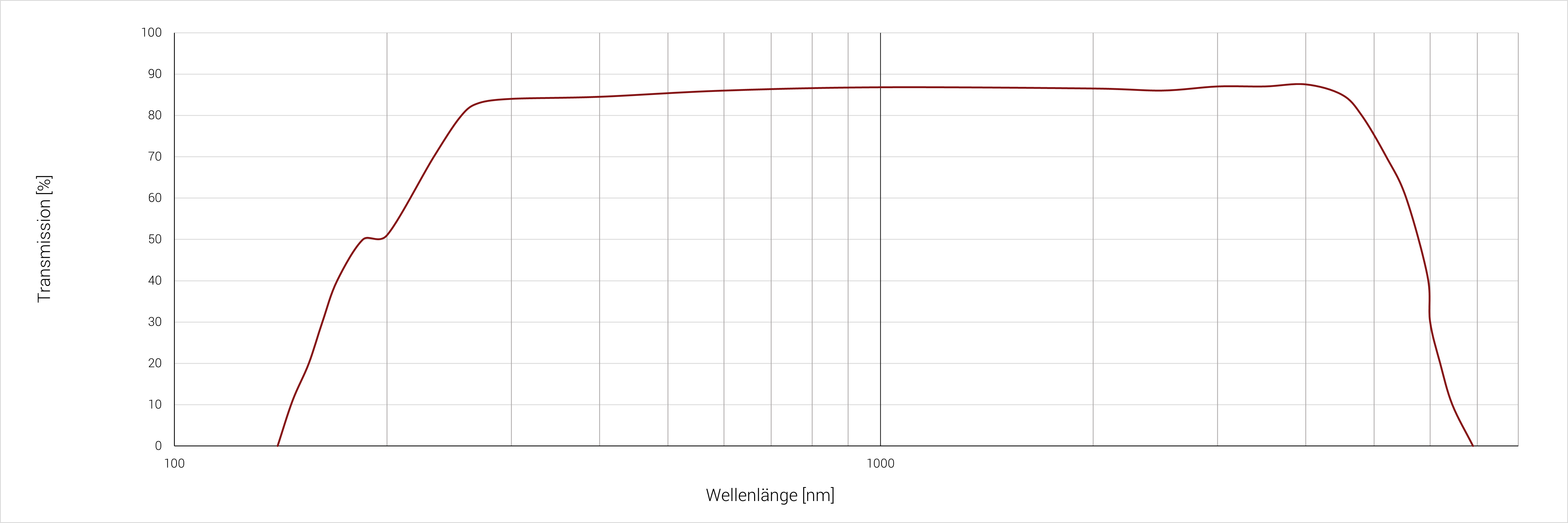

is the most sought-after material in the field of high-tech optical applications due to its unique combination of outstanding optical, physical and chemical properties. Sapphire is transparent over a wide wavelength range from vacuum UV to mid-infrared (0.18µm to almost 6µm). Due to its rhombic-hexagonal crystal structure, sapphire exhibits anisotropic behavior in many of its optical and physical properties. Therefore, the exact behavior of optical components made of sapphire is strongly dependent on the crystallographic orientation relative to the optical axis (c-axis, 0001). Sapphire exhibits slight birefringence in all crystal directions except parallel to the c-axis. Due to its extreme hardness – sapphire is the hardest of the oxide single crystals – sapphire can be

can only be processed with a few materials (e.g. diamond or boron carbide) and is therefore “scratch-resistant” compared to other materials. Thanks to its high strength, sapphire windows, for example, can be made much thinner than comparable windows made of other optical materials while offering the same performance. One more reason to use sapphire even at wavelengths close to the transmission limit. Its resistance to most chemicals, its high temperature resistance and biocompatibility open up countless other possible applications for this material outside of optics in the fields of industry, medicine & healthcare, aerospace, etc.

We preferably – but not exclusively – supply sapphire material produced using the following methods:

Kyropoulos method

This growing method produces very large crystal pears with an almost cylindrical shape and diameters of 70mm to 300mm and a length of up to 600mm. Kyropoulos crystals are characterized by high optical homogeneity and very low dislocation density (crystal defects) and can be cut in any orientation. This process is economically very efficient for the production of substrates for LED and SOS technology.

Stepanov (EFG) method

This method allows the growth of crystals with geometries close to the end product and minimizes further processing. This leads to a significant reduction in costs in many ways. These include tubes, rods (including single and multi-hole rods), plates or, for example, crucibles closed on one side. Such plates can reach dimensions of approx. 80 mm in width and over 1000 mm in length. Rods and tubes can be even longer, depending on the diameter. These crystals can be grown according to different crystallographic orientations and are used wherever the optical requirements are not so high.

Optics

Sapphire is the superior material for the most demanding optical applications, firstly because of its high transparency in the large wavelength range from around 180nm to almost 6µm and secondly because it is orders of magnitude stronger than glass. The high optical transmission in combination with almost 100% chemical resistance, mechanical wear resistance and high temperature compatibility make sapphire the leading material in optical sensor technology, spectroscopy, interferometry, etc.

Mechanics

Sapphire is widely used as a scratch-resistant cover glass for high-quality watches, scanner applications (supermarkets, logistics, chemical and pharmaceutical industries) and other applications where maximum wear resistance is required. From bearing blocks and cell phone displays to water/sand blasting nozzles!

High temperature and high pressure

Due to its unique combination of physical, chemical and optical properties, sapphire can be exposed to the highest pressure and temperature shocks. With a melting point of over 2000°C, it is an ideal material for high-temperature applications, but is also used in cryogenics. Customized high-temperature tubes and furnace windows or vacuum viewports are just a small selection from our production range.

Chemistry

Saphir ist chemisch inert gegenüber den meisten üblichen Säuren und Laugen, und das bis zu einer Temperatur von ca. 1000°C. Daher findet es in verschiedenste Anwendungen in der chemischen Industrie. Saphirrohre, -tiegel, -optiken bieten extrem hohe Standzeiten gegenüber anderen Materialien oder müssen gar nicht gewechselt werden. Saphir ersetzt mehr und mehr Quarzprodukte aufgrund seiner höheren Lebensdauer und geringerer Kontaminierbarkeit bei gleichzeitig guter UV-Transmission.

Electrical engineering

In addition to typical applications such as insulation and heat conduction, sapphire is widely used as an electronic substrate material due to its high and stable dielectric constant. By utilizing its anisotropic properties, sapphire wafers form the basis for various products in the semiconductor sector and are currently the most widely used substrate material for epitaxial layer deposition for GaN-based LEDs.

Medicine

Sapphire is a common window material for medical (and technical) endoscopes. In addition to its biocompatibility, this is due to its high resistance in contact with biological tissue and medical fluids and the ease with which it can be sterilized in an autoclave. The use of sapphire scalpels or tips for laser surgery is common practice today. In the field of beauty care / dermatology, sapphire light guides form the contact between the high-energy source and the human skin, e.g. in the treatment of pigmentation disorders, hair and tattoo removal, etc.